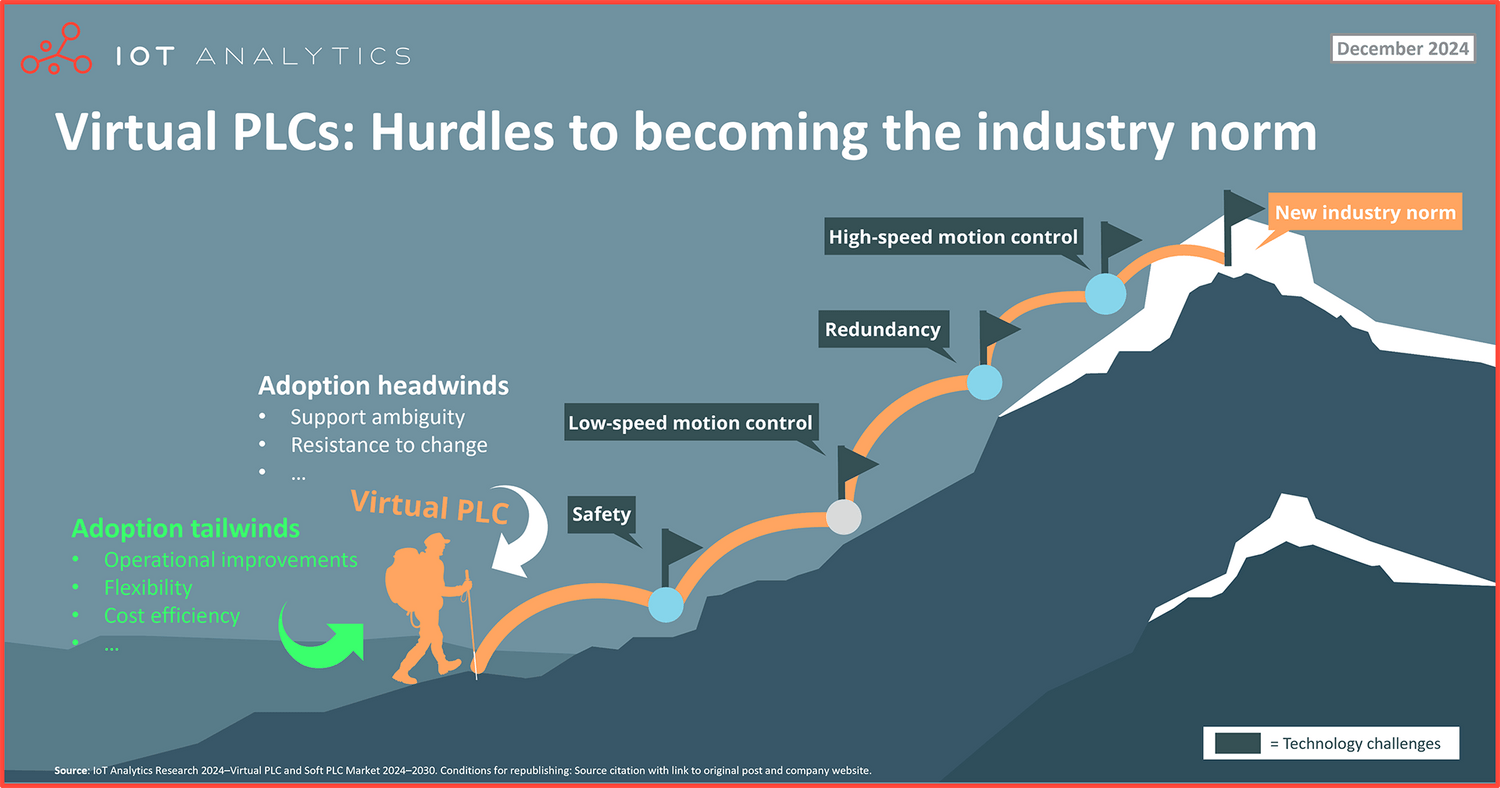

The industrial automation industry has traditionally relied on hardware-based programmable logic controllers (PLCs) to manage control logic. These devices are known for their stability and reliability. However, recent advancements are challenging this status quo. Virtual PLCs (vPLCs) represent a major shift, decoupling control software from specific hardware. This opens new possibilities for flexibility and scalability.

The Rise of Virtual PLCs

Audi is one of the pioneers in adopting virtual PLCs. The company’s Edge Cloud 4 Production (EC4P) initiative centralizes factory control by moving the control logic from decentralized, factory-floor devices to virtual PLCs running in data centers.

This shift significantly changes how manufacturing processes are managed. Instead of relying on multiple individual PLCs, Audi consolidates control into fewer, centralized virtualized units.

Running control logic in the cloud or on edge servers provides more flexibility and scalability. It makes large-scale factory management more efficient. However, the journey is still in its early stages.

Current Challenges Facing Virtual PLCs

Virtual PLCs present a revolutionary concept, but they face several limitations:

-

Lack of Technical Maturity: Most vPLC systems do not yet meet all the technical requirements of traditional PLCs. They lack redundancy, security certifications, and code portability.

-

Limited Application Support: Their maturity level is still low, restricting them to simple control tasks.

-

Lack of Standardization: The industry lacks universal standards for vPLCs.

-

Resistance from Major Players: Companies like Siemens, Rockwell, and Schneider Electric depend heavily on hardware PLC sales. Transitioning to vPLCs could threaten their current revenue models, slowing adoption.

The Potential Benefits of Virtual PLCs

Despite the hurdles, virtual PLCs offer several strong advantages:

Reduced Hardware Costs

Virtual PLCs reduce the need for multiple hardware devices. This simplifies maintenance and lowers capital expenses.

Increased Flexibility and Agility

Control logic can be deployed, updated, or expanded quickly without the constraints of physical hardware. This allows fast adaptation to production changes.

Centralized Management

vPLCs support remote updates, monitoring, and diagnostics. This improves operational efficiency and reduces downtime.

Will Virtual PLCs Become the Industry Standard by 2030?

Widespread adoption by 2030 remains uncertain. The technology is still evolving. But as companies like Audi demonstrate its value, others may follow.

To succeed, vPLCs must overcome challenges related to reliability, standardization, and security. Industry readiness also plays a role. Manufacturers entrenched in traditional systems may resist rapid changes.

Conclusion

Virtual PLCs are not yet ready to fully replace traditional PLCs. But they represent a promising future. With further development, vPLCs could become a core component of modern industrial automation by 2030.